|

Thermochemical Conversion

www.ThermochemicalConversion.com

|

Thermochemical Conversion

Business Development * Engineering

* Online

Advertising * Sales * Strategic

Marketing

|

Ad space available from the Renewable Energy Institute. For ad rates, send email to:

info@ThermochemicalConversion.com

Does your company need;

New clients

Increased revenues

Greater market share

New business opportunities

Durable Competitive Advantage ?

Will your

customers and prospective customers find your company

---- or ----

one of your company's competitors at: www.ThermochemicalConversion.com

?

"The" www.ThermochemicalConversion.com

website is the quickest, most effective advertising, business

development and marketing strategy for reaching new clients and

increasing sales.

There's only

one:

www.ThermochemicalConversion.com

Website!

Business Development,

Engineering, Online Advertising, Sales and Strategic Marketing Solutions

Renewable Energy Institute

"Changing the Way the

World Makes and Uses Energy"

info@ThermochemicalConversion.com

_____________________________________________________

“spending

hundreds and hundreds and hundreds of billions of dollars every year for

oil, much of it from the Middle East, is just about the single stupidest

thing that modern society could possibly do. It’s very difficult to think of anything

more idiotic than that.”

- R. James

Woolsey, Jr., former Director of the CIA

info@ThermochemicalConversion.com

|

Thermochemical Conversion

www.ThermochemicalConversion.com

What is Thermochemical Conversion?

Thermochemical

Conversion

is the process of converting biomass into one or more renewable fuels (biofuel

or bioenergy), whereby the biomass is either; cracked, depolymerized, or

gasified in order to produce transportation fuels such as synthetic diesel,

Fischer-Tropsch diesel, or "green" gasoline. These Thermochemical

Conversion

technologies are separately referred to as:

-

Fast

Pyrolysis

-

Gasification

-

Slow

Pyrolysis

-

Torrefaction

Thermochemical

Conversion Processes

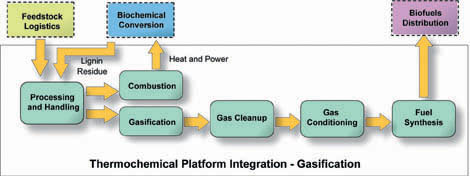

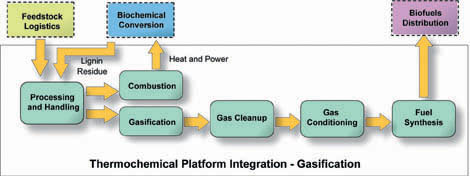

Gasification

In a gasification

conversion process, lignocellulosic feedstocks such as wood and forest

products are broken down to synthesis gas, primarily carbon monoxide and

hydrogen, using heat. The biomass feedstock is then partially oxidized, or reformed with

a gasifying agent (air, oxygen, or steam), which produces synthesis gas

(syngas).

The

quality and contents or makeup of the synthesis gas

will vary due to the different types of biomass (feedstock), the

moisture content, the type of gasifier used, the gasification agent, and the

temperature and pressure in the gasifier.

The synthesis gas

produced undergoes clean-up and conditioning to create a contaminant-free

gas having the appropriate hydrogen-carbon monoxide ratio prior to the catalytic

conversion step.

Among the

contaminants removed during clean-up are tars, acid gas, ammonia, alkali metals,

and other particulates.

synthesis gas

is

then conditioned: hydrogen sulfide levels are reduced by sulfur polishing, and

hydrogen-carbon monoxide ratio is adjusted using water-gas shift.

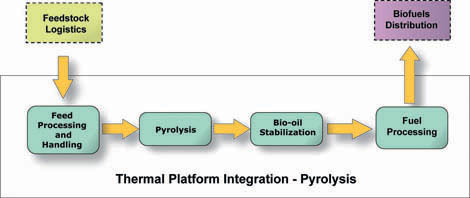

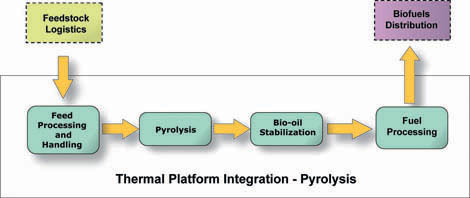

Pyrolysis

In

pyrolysis processing, one or more biomass feedstock(s) are broken down using heat in the

absence of oxygen, producing a bio-oil that can be further refined to a

hydrocarbon product. The decomposition occurs at lower temperatures than

gasification processes, and produces liquid oil instead of a synthesis gas.

Oil

produced varies in oxygen content or viscosity according to the feedstock used.

Bio-Oil

Cleanup

Oil

produced via the pyrolysis process must have particulates and ash removed in

filtration to create a homogenous product. The oil is then upgraded to

hydrocarbon fuels via hydrotreating and hydrocracking processing, which reduces

its total oxygen content.

____________________________________________________

____________________________________________________

What

is Advanced Gasification?

In

the biomass gasification

sector, there are a large number of companies that offer a wide range of biomass

gasification technologies. Some of these biomass gasification

technologies are very old and highly inefficient at converting

biomass to synthesis gas, in the waste

to energy or waste to fuel equation. Some of these are operating as low as 27%

efficiency. As a result, a large percentage of biomass is "wasted" and

the

Advanced

gasification seeks

to increase the use of biomass gasification

installations, which demonstrate improved biomass to synthesis

gas efficiencies, that in turn, increases the return on investment resulting

in more biomass gasification

plants.

Advanced

gasification technologies

ultimately reduces plant capital and operational costs through increases in biomass gasification

technologies.

What

is "Plasma Gasification?"

Plasma

Gasification - is the thermal disintegration of carbonaceous materials into

their elemental compounds in an oxygen-starved environment using a

"plasma."

Plasma

Gasification renders most waste streams, including medical/hospital waste,

chemical waste, hazardous waste, and even low-level radioactive waste,

completely safe and inert. Plasma

Gasification is the "ultimate" solution for handling most every waste

stream that is now going into landfills. In fact, Plasma

Gasification plants

will soon be built next to landfills, and take the waste that would have gone

into the landfill, and be processed by Plasma

Gasification. Eventually,

the waste and contents of landfills will be recovered and processed with Plasma

Gasification plants.

Email:

info(@)Renewable Energy Institute (.)org

The information contained on this site is

copyright protected and

cannot be

reproduced in any form or manner without our consent.

Thermochemical Conversion

www.ThermochemicalConversion.com

Thermochemical

Conversion

info@ThermochemicalConversion.com

Renewable

Energy Institute

Copyright

© 2008

All Rights Reserved